Construction of a Standardized Quality Management System for Domestic Carbon Ion Therapy Systems

Construction of a Standardized Quality Management System for Domestic Carbon Ion Therapy Systems

■QI Ying, MENG Wanbin, PAN Xin, ZHANG Mengling, ZHU Fangfang, ZHANG Fuyuan

Gansu Wuwei Cancer Hospital, Wuwei 733000, China

Abstract: In order to optimize the current quality management model of domestic medical heavy ion accelerators, this paper attempts to explore and establish standardized quality management methods and systems suitable for domestic carbon ion radiotherapy systems based on actual conditions and existing resources. It aims to provide reference information for users and managers of domestic heavy ion accelerators, thereby promoting the further advancement of the heavy ion therapy field.

Keywords: Heavy ion; Tumor; Radiotherapy

DOI:10.11842/chips.20200806001

0 Introduction

Over the past decade, the rapid development of new technologies has significantly transformed the methods of radiotherapy (RT) planning and delivery. Based on three-dimensional computed tomography (CT) planning, the use of multi-leaf collimators, improved immobilization techniques, and more sophisticated planning software, it is now possible to develop complex, high-precision treatment plans for many patients. Conventional photon radiotherapy equipment suffers from factors like depth dose distribution attenuation, causing significant damage to healthy tissues along the radiation entry path while targeting tumor cells [1]. This has led to the active pursuit of a superior radiotherapy beam: the heavy ion beam. As heavy ion radiotherapy devices are complex and huge systems, understanding their detailed working principles and potential limitations has become more difficult. Additionally, many radiation oncologists lack experience, and the rapid adoption of new technologies to increase patient throughput may paradoxically increase the risk of treatment errors [2], which can contradict the technology's aim of reducing radiotherapy errors. Regardless of how precise the radiotherapy plan is, any error during the process may not only increase treatment toxicity and reduce efficacy but also undermine patient confidence. Domestic heavy ion accelerators are in the development stage, lacking a well-established quality management system, relevant experience, and reference standards. Establishing a standardized quality management system can help detect random or systematic errors, promote improvements in existing quality assurance procedures to minimize errors, and enhance treatment quality. Influenced by the development of domestic carbon ion technology or policy formulation, research on constructing a standardized quality management system for domestic carbon ion therapy systems is necessary. Therefore, our hospital established the "Heavy Ion Therapy Center Project Construction" research project. This paper presents part of the research findings of this project, which played a role in exploring and establishing standardized quality management methods and systems for domestic carbon ion therapy, ensuring its rigor and standardization. The innovation of this study lies in exploring and establishing standardized quality management methods and systems suitable for domestic carbon ion radiotherapy systems. It further aims to provide reference information for users and managers of domestic heavy ion accelerators, promote the progress of the heavy ion cause, and better benefit patients.

1 Demand and Current Status of Carbon Ion Therapy

According to statistics, in the European population, 0.2% of patients require radiotherapy annually. Among them, 10% (i.e., 0.02% of the total population) of cancer patients could achieve better control with proton therapy. Furthermore, 20% (0.04% of the total population) of cancer patients exhibit resistance. Among resistant cancers, one-third to one-half (0.01% of the total population) are suitable for heavy ion therapy [3]. In China's population of 1.3 billion, approximately 250,000 patients are suitable for proton therapy annually, and about 120,000 patients are suitable for heavy ion radiotherapy each year. Although this data is rough, it indicates the broad market prospects for heavy ion therapy in China.

2 Overview of Construction and Operation of Domestic Heavy Ion Therapy Institutions

Since 1995, China has included "Research on Advanced Technologies in Nuclear Medicine and Radiotherapy" in the National Commission of Science and Technology's "Ninth Five-Year" Climbing Plan (B) project, with "Heavy Ion Cancer Therapy Technology" being one of the important research contents. The three major physics research institutes of the Chinese Academy of Sciences are at the international forefront in basic and clinical application research on proton and heavy ions. Simultaneously, national support and the improvement of the domestic economic level promise a broad future for heavy ion therapy in China. According to data from the "2019 Summary List of Proton and Heavy Ion Therapy Projects in China," as of October 21, 2019, there were 4 operating proton/heavy ion institutions in China: 3 proton therapy institutions and 1 institution (located in Shanghai) possessing both proton and heavy ion capabilities, with over 3,000 patients having received heavy ion treatment; 27 proton/heavy ion centers were under construction; and 46 proton/heavy ion institutions were planned [4, 5]. Heavy ion therapy in China is in a stage of vigorous development.

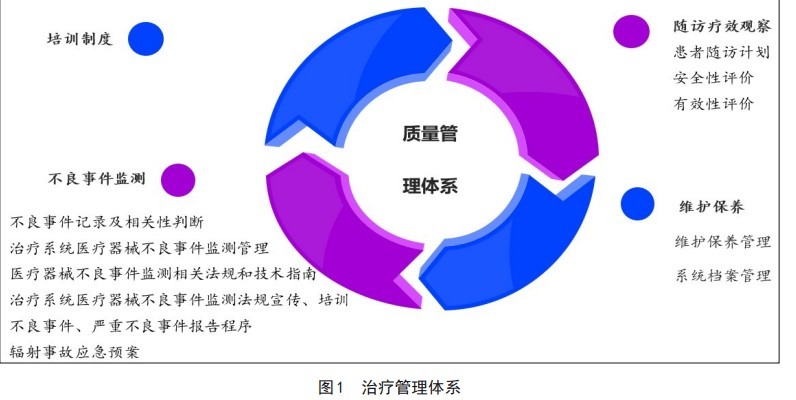

However, heavy ion therapy equipment is a new and special type of treatment equipment classified as a Class I radiation device. Standardized and systematic management and operation are crucial. Ford and Terezakis [6] reported that the probability of errors in patient radiotherapy in the United States is approximately 0.2% (1/600). To further establish and improve the quality management system for the use of carbon ion therapy systems, comprehensively strengthen quality management work, ensure organizational implementation and clear responsibilities, it is necessary to establish supervision and guarantee institutions for the quality management work of various departments involved in the carbon ion therapy system, and establish a quality management system to provide accurate data for implementation and subsequent continuous improvement. Carbon ion standardized quality management involves numerous aspects, requiring a systematic framework for standardized management and operation. Furthermore, the operation of an entire heavy ion hospital is a massive project requiring smooth and orderly functioning of all links. Relevant rules and regulations should be established to standardize the responsibilities and work content of various positions, ensuring normal operation. This study, based on the actual work situation of our unit during construction and operation, has sorted out a set of systems for peer reference in future work (Table 1, Figure 1).

Table 1 Contents of the Standardized Quality Management System for Domestic Carbon Ion Therapy Systems

| Name | Content |

|---|---|

| Usage Quality Management System | 1. Carbon Ion Therapy System Usage Quality Management Team System 2. Organizational Chart of Carbon Ion Therapy System Usage Quality Management Institution 3. Carbon Ion Therapy System Operation Quality Assurance Outline and Quality Control Plan |

| Training System | 1. Carbon Ion Therapy System User Training and Assessment System 2. Carbon Ion Therapy System Radiation Worker Training Management System 3. Carbon Ion Therapy System Staff Professional Training Plan |

| Maintenance System | 1. Carbon Ion Therapy System Maintenance Management System 2. Carbon Ion Therapy System Archive Management System 3. Standardized Clinical Diagnosis and Treatment Procedures for Carbon Ion Therapy System |

| Follow-up and Efficacy Observation | 1. Carbon Ion Therapy System Patient Follow-up Plan 2. Safety Evaluation 3. Effectiveness Evaluation 4. Follow-up Time, Frequency, and Examination Items by Site 5. Follow-up Notice |

| Adverse Event Monitoring | 1. Adverse Event Recording and Correlation Judgment Standards 2. Carbon Ion Therapy System Medical Device Adverse Event Monitoring Management System 3. Training on Relevant Regulations and Technical Guidelines for Medical Device Adverse Event Monitoring 4. Carbon Ion Therapy System Medical Device Adverse Event Monitoring Regulation Publicity and Training System 5. Adverse Event, Serious Adverse Event Reporting Procedures 6. Radiation Accident Emergency Plan |

3 Quality Control Applications Related to the Carbon Ion Therapy Standardized System

The core equipment of heavy ion therapy is a cyclotron capable of accelerating heavy ions to sufficient energy. Due to the high energy, it occupies a large area and is generally equipped with an energy selection system, beam transport system, rotating gantry, treatment head, positioning and collimation system, dose verification system, treatment planning system, treatment control system, treatment safety system, etc. Site selection for construction requires sufficient area, while also considering radiation protection issues related to large accelerators, and planning for temporary storage and treatment facilities for radioactive pollutants. According to the radiation safety management requirements of the Ministry of Ecology and Environment, radiation safety management regulations, various emergency plans, waste treatment plans, etc., must be formed to meet the review conditions of the Ministry of Ecology and Environment, environmental impact assessment reports. Operational procedures, rules and regulations, quality control, and other related content for various links require the following work:

3.1 Formulate Various Rules, Regulations, and Workflows

According to the State Council's 2017 revised "Regulations on the Supervision and Administration of Medical Devices," the 2018 notice jointly issued by the National Health Commission and the National Medical Products Administration "On Issuing the Measures for the Configuration and Use Management of Large Medical Equipment (Trial)," the National Health Commission's 2016 revised "Regulations on the Administration of Radiotherapy Diagnosis and Treatment," and other relevant requirements, formulate systems and processes such as the "Carbon Ion Therapy System Operation Quality Assurance Outline and Quality Control Plan," "Carbon Ion Radiotherapy Standard Operating Procedures," "Carbon Ion Therapy Radiation Safety Management and Equipment Operation Detailed Rules," etc. Improve relevant work emergency plans and conduct repeated drills, continuously revise and improve various standardized work procedures (SOP documents), so that all work has rules to follow and evidence to rely on, preventing the occurrence of errors and accidents.

3.2 Strengthen Personnel Training

Heavy ion radiotherapy is a special treatment requiring a large number of medical and physics technical talents. Physicists and technicians play a key role in heavy ion radiotherapy. As the equipment is a Class I radiation device, permission from the National Ministry of Ecology and Environment is required. All operators must hold certificates for operating large medical equipment and obtain certificates through training on radiation safety and protection knowledge and medical device GCP (Good Clinical Practice).

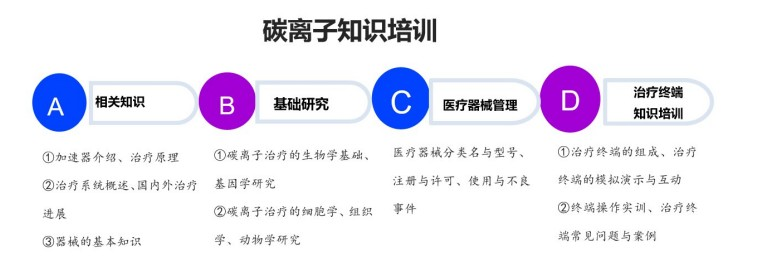

Conduct in-depth intensive training for professionals engaged in heavy ion therapy, enabling them to master the basic knowledge and latest theoretical technologies of carbon ion therapy and continuously improve, proficiently master the details of the diagnosis and treatment process, ensure standardized diagnosis and treatment, and guarantee diagnosis and treatment quality and safety. (Figure 2)

Figure 2 Carbon Ion Knowledge Training

3.3 Implement Multi-Disciplinary Consultation (MDT)

Comprehensively and strictly implement the multi-disciplinary consultation system. Patients proposed for carbon ion therapy must be reviewed by MDT. Only patients confirmed to have indications for carbon ion therapy and no treatment risks or contraindications can be treated,excluding as much as possible all potential unsafe factors.

3.4 Ensure Equipment Operation and Maintenance

The heavy ion hospital should sign carbon ion equipment operation and maintenance agreements with the equipment manufacturer. A professional operation and maintenance team should be stationed on-site, with clear details for various operation and maintenance tasks. Risk factors are potential causes of risk incidents, intrinsic or indirect causes of losses, and should be avoided as early as possible to ensure the normal operation of the carbon ion therapy system.

3.5 Strengthen Radiation Safety and Protection Work

As the equipment is a Class I radiation device, and considering the severity of events even including fatal characteristics, about 6% of radiotherapy error events belong to serious injury events [7]. Therefore, safety protection is the prerequisite for ensuring radiotherapy quality, including heavy ion accelerator mechanical safety, electrical safety, and radiation safety, such as anti-collision interlock, emergency stop switches, clear field buttons, audio-visual systems, wearing personal thermoluminescent dosimeters (TLDs) and personal dose alarm meters, real-time monitoring of room dose rates, allowing entry only after decay to management limits, etc. Permission from the National Ministry of Ecology and Environment must be obtained. Operators must hold certificates for operating large medical equipment and obtain certificates through radiation safety and protection training and medical device GCP training. Develop emergency plans for various unexpected situations, conduct regular emergency drills to ensure a rapid and proper response to radiation protection and other emergencies, avoiding major accidents. Conduct corresponding environmental impact assessment reports for the treatment equipment analysis and evaluation to ensure effective radiation protection safety, guaranteed from both institutional and hardware aspects. Hardware should establish various safety interlocks to ensure that the beam cannot be delivered if unrelated personnel are in the radiation area or if the radiation area is not locked under normal conditions. Management should strengthen personnel radiation protection awareness, establish personal occupational health files, permits for entering and exiting radiation work areas, etc., preventing radiation accidents through a multi-layer management mechanism.

3.6 Improve Quality Control and Quality Assurance Measures

Ensure patients receive accurate, safe, and effective treatment. Strictly implement established standards such as the "Carbon Ion Therapy System Operation Quality Assurance Outline and Quality Control Plan," "Carbon Ion Radiotherapy Standard Operating Procedures," "Carbon Ion Therapy Radiation Safety Management and Equipment Operation Detailed Rules," etc. Meeting requirements means meeting stated, usually implied, or obligatory needs and expectations. Only by fully meeting these requirements can it be rated as good quality or excellent quality. List the detection parameters of the carbon ion equipment, target the standard basis, standardize data operation procedures, make various diagnosis and treatment behaviors scientific and standardized, and ensure that the energy, accuracy, dose distribution, and stability of the heavy ion accelerator meet standards through the execution of equipment quality control. Before treatment begins each day, calibrate the energies needed for treatment. Weekly, calibrate the Bragg peak positions for different ion beam energies. Then, daily, calibrate the average number of ions corresponding to the unit absolute dose at this peak position. The specific energy depends on each machine's parameters. (Table 3, Table 4)

Table 2 Mechanical Parameter Inspection Form

| Inspection Content | Allowable Precision | Inspection Cycle | Remarks |

|---|---|---|---|

| Beam Central Axis | ±1mm | Monthly | Crosshair compliance |

| Light Field Indication | ±1mm | Weekly | At standard treatment distance |

| Treatment Couch: Lateral, Longitudinal Scale | ±1mm | Annually | |

| Treatment Couch: Rotation Center | 2mm | Annually | Relative to mechanical isocenter |

| Treatment Couch: Vertical Scale | 2mm | Monthly | Relative to isocenter |

| Treatment Couch: Vertical Sag (with patient) | 3mm | Monthly | |

| Laser Positioning Lights (sides & ceiling) | ±1mm | Weekly | |

| Treatment Setup, Verification System | Compliance with specified indicators | Monthly | Relevant items |

| Setup Auxiliary Devices & Immobilizers | ±1mm | Monthly or per new patient | Reliability and reproducibility of fixation |

| Field Blocking Compensators | Before new patient treatment | Processing accuracy |

3.7 Other Safeguard Measures

3.7.1 Water and Electricity Supply

Conduct daily checks on electrical performance stability. Optimize the power distribution system for key departments and links to avoid accidents. Scientifically ensure the good operation of the cooling water circulation system. The cooling water used for the heavy ion therapy accelerator is deionized water. If discharge is necessary, measures like decay by storage should be taken, and monitoring should be conducted before discharge. Radioactive indicator monitoring data should meet the "Integrated Wastewater Discharge Standard" (GB8978-1996) maximum allowable discharge concentration standards for the first category of pollutants (total β radioactivity concentration not greater than 10 Bq/L). Ensure standard-compliant discharge of radioactive wastewater and medical sewage.

3.7.2 Medical Safeguards

Patient safety events refer to events that have caused or may cause unnecessary harm to patients [8]. Therefore, it is necessary to equip supportive medical departments such as ICU, operating rooms, emergency rooms, etc. Establish and improve relevant systems, perfect various medical emergency plans, configure sufficient medical safeguard professional technicians, provide 24-hour uninterrupted medical safeguard services, and effectively prevent and resolve potential patient medical safety emergencies.

3.7.3 Information Security Safeguards

Provide network information services such as an intelligent cloud medical service platform and a dedicated radiotherapy network to fully safeguard the informatization and confidentiality needs in clinical carbon ion therapy work. Implement information security and confidentiality work comprehensively across all business areas. Ensure complete data preservation, possessing powerful functions such as multiple backups, encrypted transmission, etc., guaranteeing patient information security and equipment/facility information security. Collaborate with domestic and international hospitals possessing medical heavy ion devices to establish and improve a shared database of heavy ion radiotherapy cases. Record detailed data from diagnosis, treatment, to follow-up for heavy ion radiotherapy patients, input into the heavy ion radiotherapy case database. Establish statistical models for treatment dose, fractionation, adverse reactions, local control rate, survival rate, etc., for different tumors. Mine the inherent patterns and potential information contained in the data, which will provide basis for patient selection, treatment mode selection, etc., for more departments using heavy ions in the future, and provide a detailed data foundation for the development and research of heavy ion radiotherapy.

4 Problems Existing in the Process of Standard System Construction

(1) The quality management system for medical heavy ion accelerators basically follows that of conventional radiotherapy equipment. However, due to the large size, complex structure, and more professional operation and maintenance requirements of medical heavy ion devices, a professional operation and maintenance team is needed. The beam energy is tens of times higher than conventional radiotherapy equipment. Its physical and biological characteristics differ from photons, requiring stricter protection and more precise treatment demands. This means that under radiotherapy quality management, the operation and maintenance quality management supported by the manufacturer's technology must also be considered to achieve whole-process quality objective management. Here, the interface management between the medical institution and the operation and maintenance unit becomes particularly important.

(2) As heavy ion radiotherapy is still an emerging radiotherapy technology in China, the number of domestic cases available for reference is currently small, and treatment guidelines are not perfect. It is necessary to jointly establish and improve a shared heavy ion radiotherapy case database with domestic and international heavy ion hospitals, share heavy ion radiotherapy case data, and provide a data foundation for the continuous improvement and research of heavy ion radiotherapy.

(3) Although heavy ion radiotherapy technology has been elevated to a new height, the improvement of its quality management still needs to be further enhanced and needs to reach the stage of active participation by all staff.

5 Thoughts and Suggestions

Domestic heavy ion accelerators are in the development stage, with few user units. Quality management lacks a well-established system, and there is a lack of relevant experience, materials, and reference standards [9]. Our hospital hosts the first medical heavy ion accelerator (HIMM-1) with independent intellectual property rights. Based on our work, we explored and established standardized quality management methods and systems suitable for domestic carbon ion radiotherapy systems, making various tasks systematic, standardized, and rule-based. To accomplish this work, in addition to the contents listed in Table 1, the following conditions must be met: (1) Heavy ion radiotherapy is a new, complex, and huge treatment technology project. It requires complete allocation of medical, physical, technical, and other management talents. (2) Establish relevant clear rules and regulations to standardize the responsibilities and work content of various positions. To ensure quality objectives, perfect the systems and implement them, clarify quality management responsibilities, and always pay attention to major quality issues. (3) Emphasize the importance of quality control and also have sufficient resource investment, including manpower, funds, equipment, etc. (4) Learn from good practices, relevant experience, research results, and events significant for quality control obtained elsewhere, drawing beneficial lessons from them. (5) Other supporting medical equipment is needed, such as X-ray or proton radiotherapy equipment, CT scans, MRI, color ultrasound, simulation positioning, PET-CT, and a series of supporting examination and treatment facilities, to prepare for heavy ion treatment conditions receiving treatment or coordinated supplementary therapy. (6) Equip other medical recuperation and living facilities, etc., to organically combine heavy ion therapy with other treatment methods, complement advantages, and give full play to unique efficacy. (7) Accept the supervision work of the National Medical Products Administration and local drug supervision departments according to national regulations, effectively rectify problems raised during each supervision work, continuously improve various tasks, and ensure the safe and effective operation of the carbon ion therapy system. (8) Optimize the interface management between the medical unit and the manufacturer. Due to the highly specialized and very complex structure of medical heavy ion treatment devices, many non-conformities are bound to be encountered during operation, such as changes in beam spot size, dose rate changes, false interlocks, etc. Therefore, the technical support department of the manufacturer needs to promptly monitor and handle non-conformities encountered during device operation. Additionally, feedback from radiotherapy physicists and technicians at the treatment terminal regarding performance compliance and faults during QA & QC execution and patient treatment also requires the manufacturer's technical support department to assign highly professional personnel to communicate on-site with radiotherapy physicists in a timely manner, understand the fault situation, determine the cause of the problem, and organize personnel for timely calibration and correction, avoiding impact on the normal treatment order. (9) Collaborate with domestic and international hospitals possessing medical heavy ion devices to establish and improve a shared database of heavy ion radiotherapy cases. Input detailed data from diagnosis, treatment, to follow-up for heavy ion radiotherapy patients into the database. Establish statistical models for treatment dose, dose fractionation, adverse reactions, local control rate, survival rate, etc., for different tumors. Mine the inherent patterns and potential information contained in the data, which will provide basis for treatment patient selection, treatment mode selection, etc., for more departments using heavy ions in the future, and provide a detailed data foundation for the development and research of heavy ion radiotherapy. Simultaneously, establish a joint quality control management platform to exchange quality management experience and jointly improve heavy ion quality control levels. Facing such a huge project, many difficulties and problems will be encountered during construction and use. This paper explores some experiences gained from practical work for peer reference, to avoid detours, solve many problems in practical work, sort out a complete quality management system as early as possible, and ensure the safety and effectiveness of carbon ion therapy. However, we still have many imperfections and hope experts and scholars will provide valuable opinions and suggestions for continuous revision and improvement, to better promote the progress of the heavy ion cause and benefit the majority of cancer patients.

Table 3 Mechanical Parameter Inspection Frequency

| Item | Frequency | Item | Frequency |

|---|---|---|---|

| Field Calibration | Daily | Field Calibration | Daily |

| Isocenter | Daily | Dose Verification | Daily |

| Beam Spot Position and Size | Daily | Interlock System | Daily |

| Field Flatness and Symmetry | Daily | Ventilation System | Daily |

| Laser Lights | Daily | PDD | Semi-Annually |

| Audio-Visual System | Daily | Beam Central Axis | Semi-Annually |

参考文献:

[1] JAFFRAY D A, ATUN R, BARTON M, et al. Radiation Therapy and the Global Health Agenda[J]. Clinical Oncology,2015,27(2):67-69.

[2] DURANTE M, ORECCHIA R, LOEFFLER J S. Charged-Particle Therapy in Cancer: Clinical Uses and Future Perspectives[J]. Nature Reviews Clinical Oncology,2017,14(8):483-495.

[3] 王晓林,高天欣,韩潇,等.重离子放射治疗技术及临床应用[J].北京生物医学工程,2019(3):312-318.

[4] GUO Xiaoying, LI Yingdong. Medical Information, 2011, 24(17):5963.

[5] 王丽.我国质子重离子放疗技术发展现状及趋势[J].家庭医药.就医选药,2019(1):389.

[6] XIAO Guoqing, ZHANG Hong, LI Qiang, et al. Nuclear Physics Review, 2007, 24(2): 85.

[7] BROWN D W, SHULMAN A, HUDSON A, et al : A Framework for the Implementation of New Radiation Therapy Technologies and Treatment Techniques in Low-Income Countries. Physica Medica,2014,30(7):791-798.

[8] Radiation Protection N.181,General Guide⁃Lines on Risk Management in External Beam Radiotherapy[S].Brussels: European Commission,2015.

[9] 张俸萁,王琳,李甸源,等.碳离子束治疗肿瘤的研究进展[J].癌症进展,2019,17(22):2620-2622+2732.

Construction of the Standardized Quality Management System for Domestic Carbon Ion Therapy Systems

Abstract: In order to optimize the current quality management mode of domestic medical heavy ion accelerators, this paper attempts to establish a standardized quality management method and system suitable for domestic carbon ion radiotherapy systems according to the actual situation and existing conditions, for further providing reference information for accelerator users and managers to promote the further development of heavy ion industry.

Keywords: heavy ion; tumor; radiation therapy

Preliminary Review: Ma Shuqian

Final Review: Liu Wenyu